Naturally Occurring Prohibited Substances, Risks and Responsibilities

Date: 10 February, 2017

There are inherent risks associated with horse feed and supplements which have in recent years been highlighted by a series of high profile post-race positives for the presence of morphine; as well as high-profile FEI cases brought against prominent eventers for reserpine and more recently two dressage riders for ractopamine.

Post-race or competition positives may occur due to inadvertent contamination of a feed or supplement with an ingredient that contains a naturally occurring prohibited substance (NOPS). This can occur either during growth and harvest, or during shipping or transport. Alternatively, one of the intentional ingredients may naturally contain a substance that’s prohibited under the Rules of Racing or under FEI rules, e.g. capsaicin in Capsicum sp (red chilli pepper) or valerenic acid (a natural sedative) in Valerian sp. As feed and particularly supplement production becomes a more global operation, with ingredients often being sourced from distant continents, the risk of inadvertent contamination with prohibited substances becomes greater.

Many plants contain pharmacologically active compounds

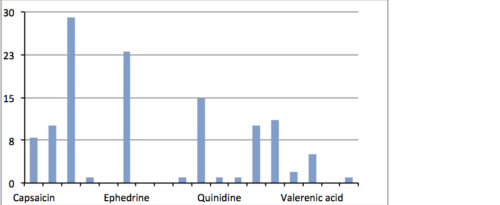

In the UK feed industry the risk of contamination is taken very seriously. Consequently, over the years, strategies have been designed and developed to reduce contamination risks from ingredients both produced in the UK and imported. These strategies combined with experience and knowledge of previous contamination events through the supply chain reduces the areas of risk associated with traditional feed ingredients such as cereals, cereal bi-products, oilseeds, pulses and forages. However, where supplements contain herbs, spices, or plant extracts the potential contamination issues can be different and create a more complex picture. This is largely due to a few key factors, for example, many plants contain pharmacologically active compounds, the supply chain is often complex and their country of origin may have less rigorous quality control systems in place. Figure A shows the number of post-race positives for substances found in herbs, spices or other plant based ingredients.

The previously mentioned episode of morphine discovered in a post-race sample was reportedly due to poppy seed contamination of the feed. Many are unaware that morphine-containing poppies (Opium poppies; Papaver somniferum) have been grown in discrete locations in the UK, under a specific license, for the harvest and subsequent manufacture of pharmaceuticals for the health service. It’s worth noting that the commonly encountered red field poppies do not present a significant risk, as they contain only extremely low levels of morphine, if any.

Opium poppies are grown as a break crop, where the farmer is only involved in the preparation of the land and all other aspects of growth, harvest and production including, seed drilling, agronomy, harvest and processing is under the strict control and management of the license holder. The poppy seed head delivers the greater amount of morphine whereas the poppy seeds themselves contain a very low level of morphine, which renders them all but commercially redundant.

In the human food chain poppy seeds and fragments of spent seed heads can find their way into the food chain, sometimes intentionally, you’re likely to be familiar with poppy seed topped rolls in the bakery! The European Food Standards Agency (EFSA) has recently investigated morphine entering the human food chain and as it’s not currently listed as an undesirable substance there’s no minimum legal limit for morphine in human food.

Whilst the residual level of morphine in this spent material may be physiologically irrelevant to humans, it remains problematic to riders and trainers. The sports regulatory bodies including the FEI and BHA may choose to take a pragmatic view of post-race or post competition positive results proven to be undisputedly caused by feed contamination. However, morphine is a significant analgesic and therefore must be regulated in a way that prevents its potential for abuse. One has to acknowledge that the horse will have competed or raced with the ‘drug’ in its system and as there remains no ‘official’ threshold for morphine in post-race samples, a line must be drawn. Undoubtedly, discussions will be on going as to the physiological significance of the often low-levels detected.

BETA-NOPS® code was developed to reduce risk of prohibited substances

Within the equine industry, some companies have signed up to an industry led quality control scheme designed to safeguard the interests of both consumers and its feed members against the risk of prohibited substance contamination of feed and supplement products. Many companies see such quality assurance schemes as immensely beneficial.

The key aspects of good quality control are to understand where the risks lie within each part of the supply chain and having a long-term, well-established relationship with your suppliers is important. Using an appropriately accredited manufacturing facility that you work with closely is also crucial. It’s also especially important that the sports industry and feed and supplement companies help ensure that everyone involved in the supply and manufacturing chain, such as, farmers, harvest contractors, ingredient processors, hauliers, storage suppliers, riders, trainers and stable staff understand the importance of prohibited substances, and the significance and consequences of minute levels of contamination. The feed industry as a whole takes this ongoing education process very seriously and this forms a fundamental part of the stringent quality control processes involved in feed production.

It is helpful to have collaboration between different manufacturers so that any concerns regarding ingredients or finished products perhaps following analysis can be shared for the common good. Ensuring that marketing claims about prohibited substances are factual and not misleading is also essential, for example, a ‘free from prohibited substance guarantee’ is not acceptable, as it’s not possible to deliver and riders and trainers should be cautious of companies who offer such a guarantee. Equally, a company or representative that cites the tacit approval of a product by the BHA or FEI are misleading their customers, as these organizations never give such approvals or endorsements.

Inevitably any companies that are accredited to any industry schemes are likely to be audited annually, to ensure their compliance to the ‘rules’, allows continued access to the scheme. The audit process will concentrate on ensuring robust risk assessment and quality control systems are in place to mitigate the risk of contamination with prohibited substances and a certain amount of feed or raw material testing for prohibited substances should be undertaken. The level of analysis or testing should be determined by the perceived risk which can therefore vary from product to product. Generally, the testing protocol performed indicates the absence of a defined range of prohibited substances, which may include caffeine, theobromine, theophylline, hyoscine, hordenine, atropine and morphine (see Table A). This list of tested contaminants was originally established as a result of historical episodes of contamination of feed impacting on racing.

| Contaminant | Source |

|---|---|

| Caffeine | Coffee, biscuit meal |

| Theobromine | Cocoa |

| Morphine | Poppies e.g. P Somniferum |

| Atropine | Crop weed e.g. Atropa sp |

| Hyoscine | Crop weed e.g. Datura sp |

| Hordenine | Sprouting grains |

Education is key in reducing the risks of prohibited substances

Although riders and trainers should absolutely expect a company marketing a feed or supplement into all competitive horse sports to follow rigorous quality controls and take all reasonable precautions to minimize contamination risks, riders and trainers themselves also have a responsibility to understand the risks and actively manage them. After all, it is the rider or trainer’s reputation and livelihood that is at stake. To assist them with this, information on prohibited substances is provided to newly licensed trainers during the mandatory BHA trainers’ course. Also, the NTF has previously held well-attended seminars on the subject. The FEI also have an excellent section of their website concerning ‘clean sport’ and how riders can educate themselves and keep abreast of new information. In addition the FEI operate a list of prohibited substances that is updated regularly (www. inside.fei.org/fei/cleansport)

The first step riders and trainers can take is to be totally aware of what is fed to their horses and the main ingredients in all of those products, whether a feed or a supplement. This information is readily available, as it’s a legal requirement for companies to detail this on the packaging. When choosing feed and supplement products, trainers would be advised to enquire about the quality control systems that the manufacturer has in place to reduce the risk of contamination with prohibited substances. This is likely to consist of a risk assessment, raw material traceability and testing of both the ingredients and the finished product. Keep in mind that many companies do not manufacture the product themselves and may contract the process to another manufacturer; nevertheless they should still have an equally robust system of traceability and quality control. Likewise, some small companies may have a small-scale in-house production, but their procedures and systems should be similarly examined. For example, Racing Blue the manufacturers of STORM undertake a rigorous quality control program that includes each batch of raw material and finished product being tested for a specified wide range of prohibited substances.

Historic cases suggest that where a rider or trainer uses a product manufactured outside of the UK, deeper questioning of the marketer is advisable, as their required processes may not match UK criteria. For example, certain substances that are allowable in feed production in other countries, such as the US and Australia may be regarded a prohibited under the Rules of Racing in Europe. Feeds or supplements that are produced on single species manufacturing lines can reduce the risk of contamination with prohibited substances.

In addition to this, riders and trainers need to keep in mind and evaluate the increased risk around the types of ingredients used in supplements and take this into consideration when making product choices. It’s worth seeking independent guidance on the potential risk of the occurrence of prohibited substances from industry experts before a new product is introduced.

In-yard procedures can help mitigate the risks of prohibited substances

Riders and trainers would be strongly encouraged to introduce their own procedures in addition to those implemented by feed and supplement companies. In much the same way that veterinary records are kept, maintaining a list of feedstuffs used regularly for individual horses is best practise, and extremely useful should a post-competition or race sample return as positive. Putting a simple process in place to ensure a record is kept of delivery dates, batch numbers and invoices, as well as the retention of all associated delivery notes and other paperwork, provides further evidence, if and when needed, to establish the route of contamination. Furthermore, retaining samples of each batch of feed and supplement for about 3 months is a beneficial process to implement, as this is the period of time over which a post-race positive is possible and the consequent regulatory process will last. Representative samples of feed (500g) and a supplement (100g) should be stored in a sealed plastic bag and labelled with the product name, batch code and purchase date. In the event of an investigation the record keeping along with the retained samples will provide vital evidence and details of the particular products fed. It’s to be expected that most reputable manufacturers would maintain retained samples that could be re-examined if a problem arose; this is perhaps a question to be asked of any supplier. However, it’s a sensible precaution for the rider or trainer to take these extra steps.

Quality control / accreditation schemes have brought considerable benefit to the racing industry, however, historical positive cases with morphine and other substances demonstrate that it’s not infallible. Lessons will always have been learned, which will further improve the systems in place. Equally however, riders and trainers have a pivotal role and should ensure they keep informed and up to date with the risks, so that they are able to make the best possible feeding and feed management choices.

Prohibited Substance Data

Fig A – Number of post race positives for herbal or plant based prohibited substances

*Source of data – International Federation of Horseracing Authoroties (IFHA) recent annual prohibited substance reports